Training enhances the value of new technology

One reason technology doesn't diffuse more quickly - you need to know how to use it well

This post was jointly written by me and Karthik Tadepalli, economics PhD student at the University of California, Berkeley! Learn more about my collaboration policy here.

This article will be updated as the state of the academic literature evolves; you can read the latest version here. You can listen to this post above, or via most podcast apps here.

Technology has advanced by leaps and bounds in the past few centuries, but much of that progress is still limited to the richest countries. Even though incredibly advanced technologies have been invented and used in rich countries, they diffuse very slowly to the developing countries where most people live.1 For example, Comin and Mestieri (2014), a review of the literature on international technology diffusion, tracks the diffusion of 25 different technologies across the world, ranging from the telegraph to the internet. Across this set of technologies, the typical lag between when a technology is invented and when it first shows up in a country is 44 years. Comin and Mestieri argue that, while this delay to first appearance has contracted over time, there has been much less improvement on rates of overall diffusion - that is, when does the typical person in a country have access to the technology.

Why does this happen? Why don't new technologies spread quickly throughout the world, benefiting billions of people? You can fly anywhere in the world in a day or two, so why don’t useful technologies spread at a similar rate?

This is an enormous question with many answers. In this post, we’ll focus on one particular answer that applies to technologies for producing goods, rather than new consumer products: the complementarity between technology and knowledge.2 In other words, new technologies improve productivity, but they improve productivity more when paired with knowledge on how to use them. Without training, the new technology may only be a slight improvement over the old technology, or perhaps no improvement at all.

For example, a tractor can be much more efficient than human workers at plowing a field, but at a minimum you need to know how to drive it to get that benefit. But there are a lot of other things you may need to change to get the most benefit out of it. You need to know how to maintain it. How to plant crops to make best use of it. In the longer run, you may be able to get more benefit if you expand the size of your farm. New technologies can be bought and sold on the market, but the knowledge needed to use new technology may be much more difficult to acquire, even from a good training manual. If this is true, new technologies will be less beneficial to recipients who don’t have the knowledge to use them effectively - and thus, they may not spread as much as we expected.

Two papers, one by economist Michela Giorcelli, the other by Bo Li and Giorcelli again, explore this explanation by studying historical technology transfer programs which provided access to new technologies in some cases, and new technology plus related training in other cases. Let’s start with Giorcelli (2019), which studies the Productivity Program, a Marshall Plan program from 1952-1958 that aimed to boost the productivity of Italian firms as a bulwark against communism. Italian firms could apply for subsidized loans to purchase advanced technologies, could apply to send their managers to the US for training, or both. The program was motivated by US officials touring European plants during post-war reconstruction efforts and observing that labor productivity was much lower than in American factories. The problem, according to a 1949 US Bureau of Labor Statistics report on Italian plants, was:

Workers are not trained by the firms, and the flow of work and the employees’ operations are not carefully studied and integrated. […] The insufficient critical allocation of labor, and the accumulation of numerous small losses in efficiency determine an excess of workers per output, estimated between 50 percent and 400 percent. […] Plants are not well-organized and often work areas, lighting, and ventilation are not adequate. There is less (compared to the US) thorough maintenance of machines, equipment and tools, that result in more frequent breakdown and work interruptions. […] Modern marketing strategies are undeveloped, and distribution channels are old-fashioned.

The trouble with evaluating a program like this is that the people who apply are not random. For example, maybe only the most ambitious Italian firms applied for the program; their productivity is higher, but it always would have been higher, whether they receive new technology and training or not, because these were ambitious folks. Indeed, Giorcelli finds firms that applied to the program were 25% more productive than those that did not, and much less likely to be family run. So you can’t simply compare what happens to the firms that participate in the program to the ones who did not.

Unfortunately for the Italian firms, after more than 3600 had applied, the budget to the Productivity Program was cut as a consequence of the US’s deepening involvement in the Korean War. As a result of this budget cut, the US limited the program to only a few districts within Italy, leaving out firms from other districts that had previously been accepted into the program. Giorcelli compares the outcomes of firms who participated in the program to firms who applied to the program but unexpectedly found they were located in ineligible regions and so did not receive any technology transfers or training.

She finds:

Firms that received advanced technologies (but not training) had higher survival rates, sales, employment and productivity than firms that were ineligible because of the budget cut. Productivity steadily rose to a level 10% higher than ineligible firms after ten years, and then stayed near this level.

Firms that sent their managers to the US, but did not receive advanced technology, also had higher survival rates, sales, employment and productivity than firms that were ineligible because of the budget cut. After 15 years, participating firms had 50% higher productivity than excluded ones. In other words, training boosted long-term productivity on its own.

The productivity effect of receiving both technology and training was larger than the sum of the individual effects. In other words, training and technology were complements.

What explains the stark difference in effects, and especially why training had a compounding benefit? In particular, why didn’t access to modern manufacturing technology alone produce larger productivity gains?

Giorcelli finds that firms which received management training implemented a number of new practices that augmented the long-run efficacy of their new technology. They invested much more in worker training and machine maintenance. Machine downtime and worker injuries dropped significantly in these firms. More broadly, before the Productivity Program, less than 6% of firms reported training their workers, or spending on marketing, on their balance sheets. Afterwards, nearly 100% of firms that received training reported both of these activities on their balance sheets, while firms that received only technology did not adopt either of these practices. It seems likely both of these led to less wastage and higher sales in the short run. Moreover, in the long run, firms that received training reshaped their business organization; they expanded to have more plants, they increased their manager-to-worker ratio, and they were more likely to be professionally-managed rather than family-managed. Each of these decisions may also have increased productivity over the long run.

The core finding - that technology without training has a small benefit, while technology with training has an amplifying effect - is recreated in Giorcelli and Li (2023). Giorcelli and Li focus on a different technical assistance program: the 156 Projects, a technology and knowledge transfer agreement between China and the Soviet Union in the 1950s. At the time, China was a pre-industrial economy, with two-thirds of its workforce in agriculture, and Chinese leaders wanted to industrialize rapidly. The Soviet Union was its ideological ally and was technologically competitive with the US in heavy manufacturing. The 156 Projects were a collection of planned industrial clusters in China that would replicate highly successful manufacturing clusters in the Soviet Union. The goal was to transfer both Soviet machinery used in their most successful factories, as well as to have Soviet engineers train Chinese engineers and production managers in how to use the machinery.

It looks like organizers of the program fell victim to the Planning Fallacy: rollout took a lot longer than anticipated. The Soviet Union did not have capacity to quickly meet the demand from China for new capital goods. According to Giorcelli and Li, pressure to meet ambitious production targets led to a series of production disasters: fires, floods, and railway accidents destroyed advanced machinery and led to severe delivery delays. Meanwhile, there was also a shortage of Soviet experts as well; many experts had to first learn about the new production technologies in the USSR, before moving to China to offer training courses. These, in turn, often had to be done with translators - it took longer than expected for experts to learn Chinese.

And then the 156 Projects were abruptly canceled in 1960, as Sino-Soviet relations deteriorated. Due to the afore-mentioned delays, all of the plants had already been built and begun operating with Chinese machinery, with a plan to transition to Soviet machinery as soon as the Soviet Union could deliver it. At the time of cancellation, some of the clusters in China had received nothing, others had received Soviet machines, and others had received both Soviet machines and Soviet training. Giorcelli and Li argue that who got what was more or less random (fires, floods, accidents, slow learners, etc.) rather than strategic.

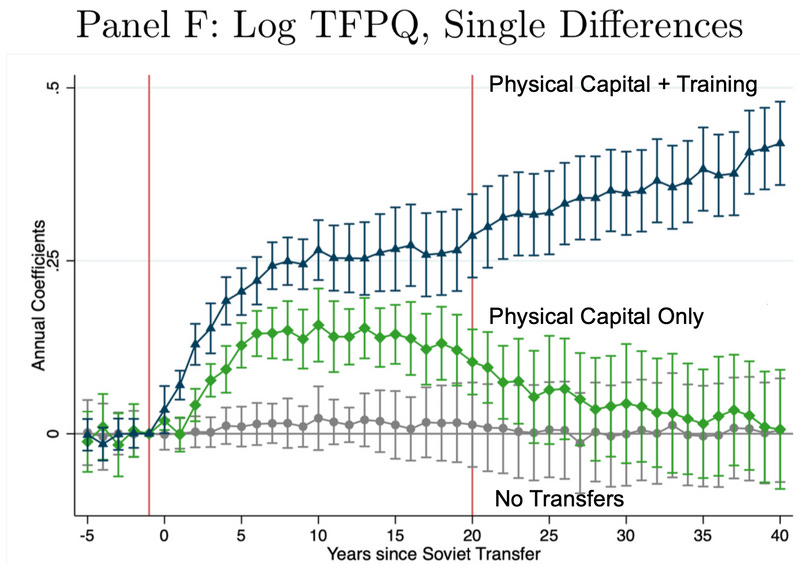

Giorcelli and Li find:

Plants that received only Soviet machinery saw a temporary increase in productivity relative to the plants which received nothing because of the Sino-Soviet split. This increase slowly decayed to zero (though it was still positive after 20 years).

Plants that received both Soviet machinery and training saw a permanent increase in productivity, which compounded for decades. In the steel sector specifically, they produced both a higher quantity and higher quality of steel than the plants that received Soviet machinery alone.

Why did training by Soviet engineers have such a compounding effect, while machines alone had so little effect? One reason is that despite being state-of-the-art at the time, Soviet machines became obsolete in the 1960s, and plants that received training were more likely to be able to internally develop more advanced machines. In the steel sector in particular (which made up 45% of the 156 Projects), Soviet open-hearth furnaces were made obsolete by continuous-casting furnaces. After 20 years, plants that received Soviet training were 78% more likely to have continuous-casting furnaces than plants that received only machines. In contrast, plants that received only machines were no more likely to have continuous-casting furnaces than plants that received nothing, suggesting that receiving technology without training did not induce future innovation.

Another explanation is that plants that received Soviet training continued to offer technical training to their own employees, long after the Soviet connection was severed. In support of this explanation, Giorcelli and Li find that plants receiving Soviet training had a larger share of (Chinese) engineers and high-skilled technicians, and a lower share of unskilled workers, compared to plants that received only Soviet machines. Since China heavily restricted internal migration at the time, it’s likely that these engineers and high-skilled technicians were trained internally rather than at other plants elsewhere in China. This within-firm training would be especially important given that they developed their own machines to replace the Soviet machines, and would need to subsequently train their employees to use the new machines they had developed.

These two papers have pretty similar conclusions, even though their settings differ in many ways. The 156 Projects specifically focused on heavy industry manufacturing, whereas the Productivity Program was not sector-specific and focused on small and medium-sized firms. Whereas the Italian Productivity Program focused on management training, the training received as part of the 156 Projects was largely engineering knowhow, so the conclusion is not driven by any specific type of training. Italy was a relatively modern economy at the time, whereas China was still predominantly agrarian, so the conclusion isn’t necessarily specific to certain levels of development in the receiving country. Despite all of these differences, the complementarity between technology and training is evident in both programs.

Furthermore, in both cases, within-firm training seems to have been a key reason knowledge persisted over time. Machines break and become obsolete, but knowledge is self-replicating. Once some workers within a firm are trained, they can train other workers, who can train even more workers (see Importing Knowledge for documentation of a similar dynamic when people skilled in a particular technological domain immigrate). In particular, while some kinds of knowledge can become obsolete, other forms of knowledge, such as a process for conducting research and development paired with an improving mindset, can mean obsolete knowledge gets replaced by newer and better knowledge.

This is a compelling story, but it can’t be the whole story; after all, it only makes sense if knowledge can’t be acquired alongside technology. Why would that be the case? Shouldn’t firms have a powerful incentive to acquire the knowledge to use advanced technology, if it’s so beneficial? Shouldn’t manufacturers of new technology have an incentive to offer training, if it makes the products so much more valuable to their customers? In the future, we hope to look at this and other frictions that slow the diffusion of technology across the world.

Thanks for reading! As always, if you want to chat about this post or innovation in generally, let’s grab a virtual coffee. Send me an email at matt.clancy@openphilanthropy.org and we’ll put something in the calendar.

For our economist readers, we’re using the word “technology” in the colloquial sense here: think better factory machines. We’re not using the term in the broader sense often used by economists - roughly, a means of converting a set of inputs into outputs (a means which might, in fact, include training!).

See Verhoogen 2023 for a recent overview of many of these other factors.